phase-change materials (PCM)

The Ixelles Employment project incorporates all the basic principles to achieve the passive standard.

Heating requirements are significantly reduced:

+ The building’s envelope is well insulated:

+ The air tightness is very good;

+ The building is equipped with double flow ventilation with a high performance heat exchanger.

Summer comfort is ensured due to passive cooling strategies:

+ External loads are limited due to solar protections.

+ The equipment chosen is energy efficient, which at the same time enables the limiting of internal loads;

+ The remaining loads are dissipated due to the use of materials with high inertia and natural night time ventilation.

A first in Belgium!

However, the building’s quality also resorts to the quality of the materials used. This is why we are choosing them due to studies on the impact of grey energy, used to produce them and transport them and a study on their impact on health. Furthermore we are using innovative materials.

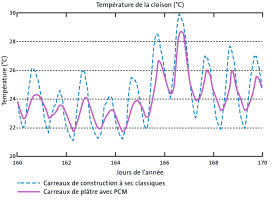

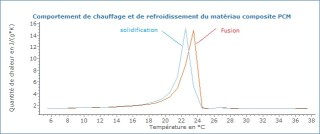

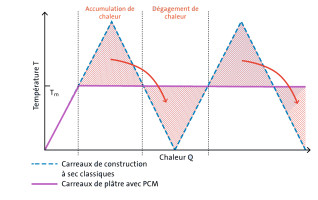

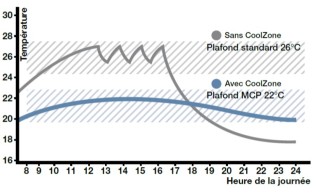

In this project, innovation involves using phase change materials (PCM – Phase Change Material). These are capable of storing large quantities of thermal energy and and keeping it for a long time with very little loss. It is the changes between solid and liquid state of a high quality paraffin that make this possible: by melting, after having reached a certain temperature, the paraffin stores the thermal energy which is released (fusion heat) this enables avoiding a heat build-up during the day. During the night, this heat is evacuated by the material which solidifies again.

This phase transition can be repeated as often as necessary. During warm periods, so that the temperature decreases sufficiently and the PCM goes back into a solid phase, an efficient night cooling is put in place in the project by means of mechanised opening of certain windows. The PCMs combined with natural night time ventilation enable the hours of over heating to be greatly reduced and improve the thermal comfort of all the spaces (premises with internal loads and different occupation: individual offices, open plan offices, training rooms,…) while reducing cooling costs.

Stated more simply this could be compared to the phenomenon of an ice cube in a drink. Of course here, there is no risk of the product running out as the capsules are inserted in a gel held between aluminium foil.